Why Design for Manufacture shouldn't wait until the end

GB Electronics (GBE) provides comprehensive mechanical design services, supporting every stage of product development across West Sussex, the wider South East, and beyond.

From precision CAD modelling using SolidWorks® to design for manufacture (DfM) and assembly (DfA), we ensure every product is optimised for performance, reliability, and efficient production.

Our experienced in-house team delivers electromechanical integration, prototyping, and compliance-ready designs, helping clients across Worthing, Crawley, Chichester, and beyond bring robust, scalable products to market.

Our mechanical design services include:

Looking for a mechanical design partner in West Sussex? Let's discuss your project.

Why Choose GBE for Mechanical Design & Engineering Services?

At GBE, our mechanical design work is never isolated—we integrate seamlessly with electronics, firmware, and software teams to deliver complete product development solutions. This cross-functional approach eliminates design conflicts early, shortens development timelines, and ensures full system compatibility from the start.

Our designs are engineered for real-world conditions: from thermal management and material fatigue to ingress protection and regulatory constraints. Every detail is modelled with long-term reliability, cost-efficiency, and manufacturability in mind.

With extensive experience across medical, industrial, and consumer product sectors, we understand how to align mechanical functionality with user expectations, safety standards, and production realities. Whether you're scaling a prototype or launching a high-volume assembly, our team ensures your design is ready.

Bringing a product to market demands more than functional design—it requires foresight into how components will behave, assemble, and endure under real-world conditions. At GBE, we develop mechanical solutions that are engineered for manufacturing, scalability, and reliability from the outset.

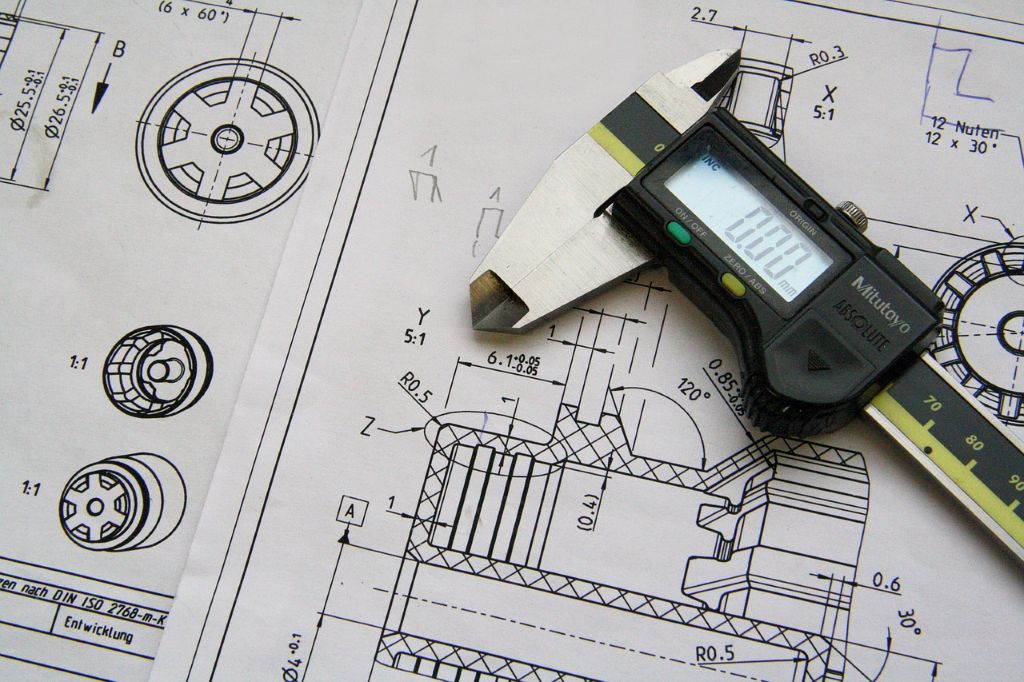

We use SolidWorks® to create detailed, production-ready CAD models that incorporate mechanical, manufacture, and material considerations. Whether it's an injection-moulded casing, a CNC-machined bracket, or a sealed assembly, each design is refined to minimise complexity and assembly time.

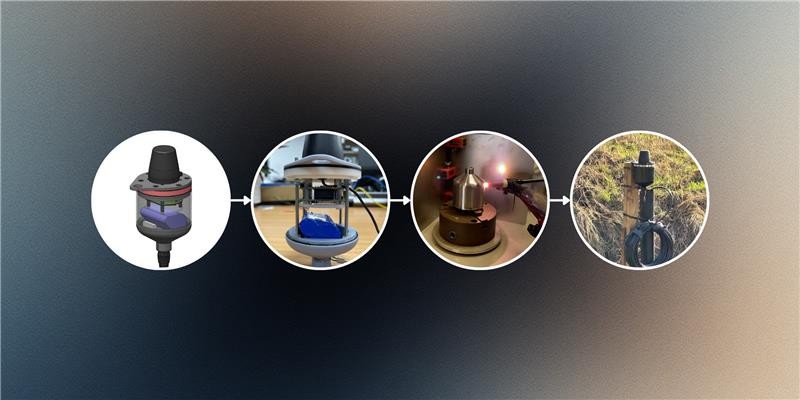

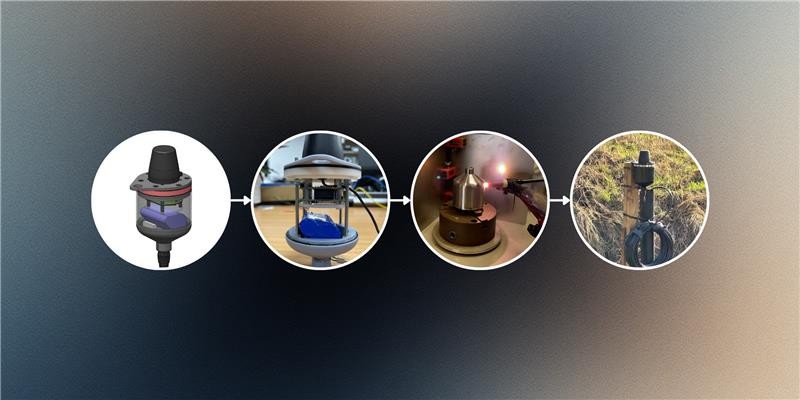

Prototyping forms a critical part of this process. Early test models allow us to validate mechanical performance, identify risks, and fine-tune components before committing to tooling or production runs. This agile approach reduces waste, accelerates development, and ensures readiness for scale-up.

From complex electromechanical systems to single-part components, our mechanical designs are precise, production-informed, and built for lasting performance.

Meeting regulatory standards isn't an afterthought—it's engineered into every component we design. At GBE, we ensure mechanical elements are built to comply with key UK, EU, and industry-specific requirements from the earliest design stages.

We design enclosures and assemblies to achieve IP ratings for dust and water protection, particularly important in industrial and medical applications. Our team also supports CE marking and UKCA compliance by integrating material selection, safety requirements, and mechanical tolerances that align with relevant directives.

By addressing compliance considerations during CAD modelling and prototyping, we help our clients avoid late-stage redesigns, reduce testing failures, and accelerate time to market.

Whether your product needs ingress protection, medical-grade sealing, or precise material specifications, we design with certification success in mind.

Unsure about CE, UKCA, or IP ratings? Speak with us about compliance-ready design.

Effective mechanical design is not developed in isolation—it must integrate flawlessly with electronics, embedded systems, and manufacturing processes. At GBE, our collaborative workflows ensure that every design decision supports the technical, operational, and commercial goals of the final product.

From the earliest stages, our mechanical engineers work alongside in-house electronics and software teams to align structural, thermal, and spatial requirements. This reduces design conflict, shortens development cycles, and ensures every component works together as a cohesive whole.

We refine designs through CAD modelling, prototyping, and functional testing, identifying and resolving challenges around material choice, assembly sequences, and thermal behaviour before they escalate. Whether designing for handheld medical devices or industrial systems, we engineer with both product performance and manufacturability in mind.

By involving all stakeholders early—engineering, compliance, and manufacturing—we reduce risk and develop better products more efficiently.

Tell us about your project

Ready to embark on your next project? Contact GB Electronics today and let us discuss how we can assist you in creating efficient, compliant, and innovative electronic products. Reach us at +44 (0) 1903 244 500 or email us at info@gbelectronics.com

GB Electronics

GB Electronics