At GB Electronics, we specialise in providing exceptional prototype PCB assembly services tailored to meet the intricate demands of your projects and first stage realisation.

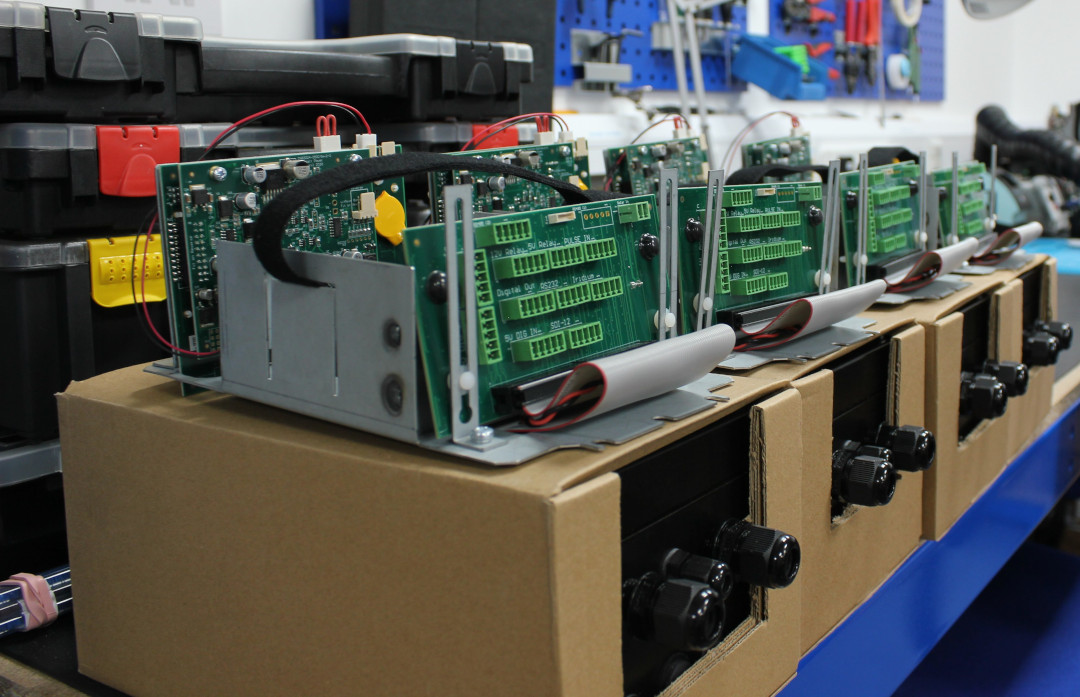

Our expertise extends to creating both 'one-off' prototypes and small batches for pre-production testing, verification, and evaluation.

With over 35 years of experience, we aim to ensure your printed circuit board (PCB) prototype meets your exact performance requirements, enabling a seamless transition up to full-scale production.

Choosing GB Electronics for your prototype PCB assembly comes with a plethora of advantages:

Why Choose GBE for Your Next PCB Prototype Assembly?

Choosing GB Electronics for your next PCB prototype assembly ensures you are partnering with a company that prioritises quality, efficiency, and customer satisfaction. Our 35 years plus of experience across various sectors in the electronics industry means our team brings a wealth of knowledge and expertise to each project. We treat every prototype assembly with the highest care and precision, applying rigorous testing and quality control measures to ensure your PCB meets or exceeds expectations.

Our collaborative approach means we work closely with you from concept through to final testing, offering flexibility to meet your project's needs, whether it requires a single prototype or a small batch for pre-production testing. We're committed to delivering your PCB prototype on time and within budget, leveraging our technical proficiency and industry experience to provide cost-effective, high-quality solutions.

By choosing GB Electronics, you're not just getting a service provider; you're gaining a trusted partner dedicated to the success of your project, reflecting our proven track record in the industry and commitment to excellence.

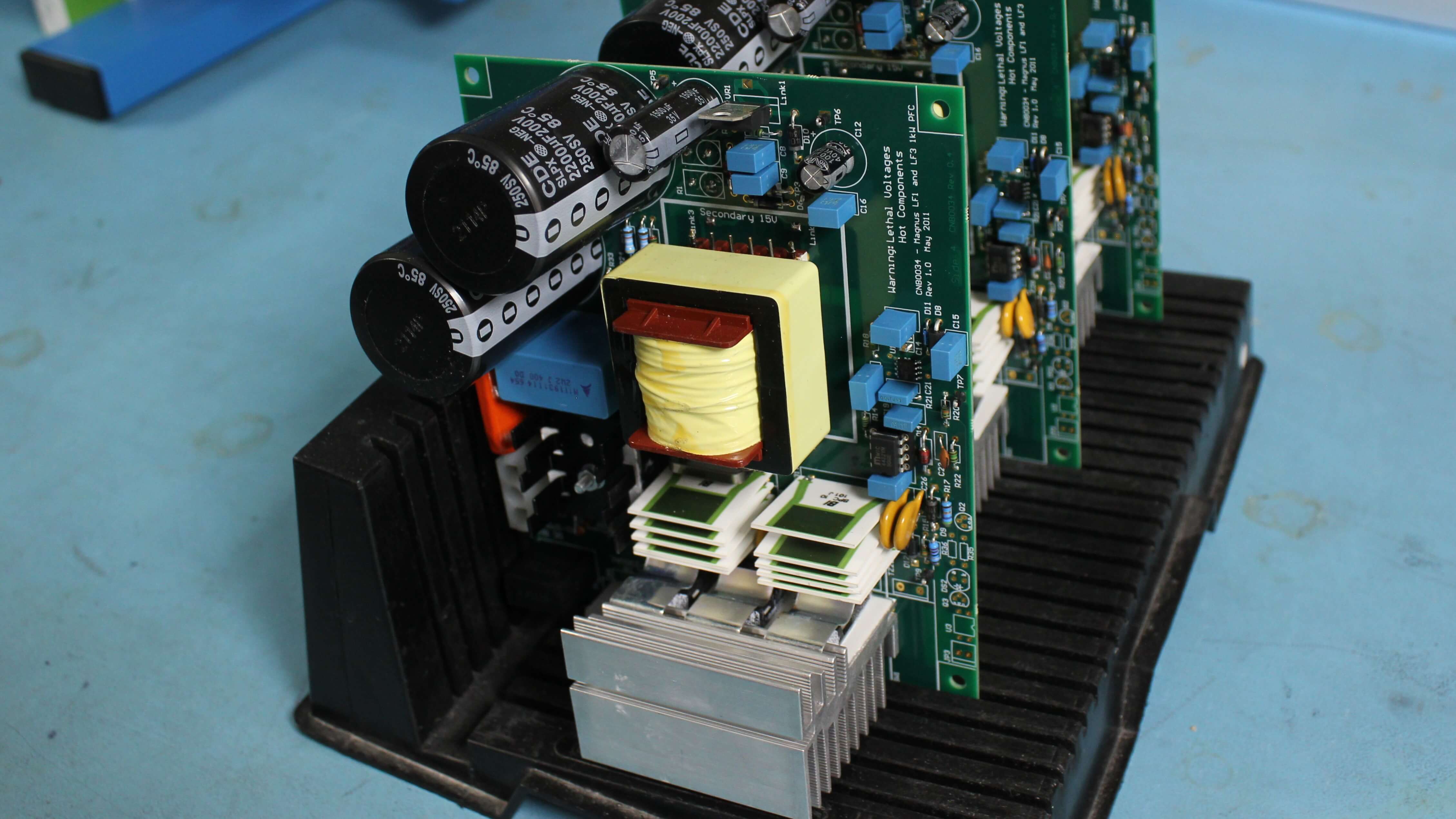

A prototype PCB is a preliminary model of a printed circuit board designed to test, verify, and validate the functionality and performance of an electronic circuit.

This crucial step in the PCB development process allows designers and engineers to identify and rectify potential issues before proceeding to mass production, ensuring the final product meets the desired specifications and standards.

PCB prototyping assembly services are essential for refining and validating electronic devices before mass production, ensuring they meet the highest performance and reliability standards.

These services enable early detection and resolution of design errors, saving time and resources by preventing costly revisions later in the process. Prototyping allows for comprehensive functional testing, ensuring the circuit meets all operational requirements. It also enhances cost efficiency by reducing the risk of expensive rework during mass production and accelerates the product development cycle, leading to faster market entry. Moreover, prototyping facilitates stakeholder feedback, allowing for customisation and optimisation of the design.

Overall, PCB prototyping minimises the risks associated with product failures, safeguarding brand reputation and financial investments by ensuring the launch of reliable, high-quality electronic devices.

Tell us about your project

Ready to embark on your next project? Contact GB Electronics today and let us discuss how we can assist you in creating efficient, compliant, and innovative electronic products. Reach us at +44 (0) 1903 244 500 or email us at info@gbelectronics.com