Precision, Speed, and Scale: The Future of Surface Mount Assembly at GB Electronics

GB Electronics is a leader in surface mount PCB assembly, delivering sophisticated solutions to meet the needs of the contemporary electronics landscape.

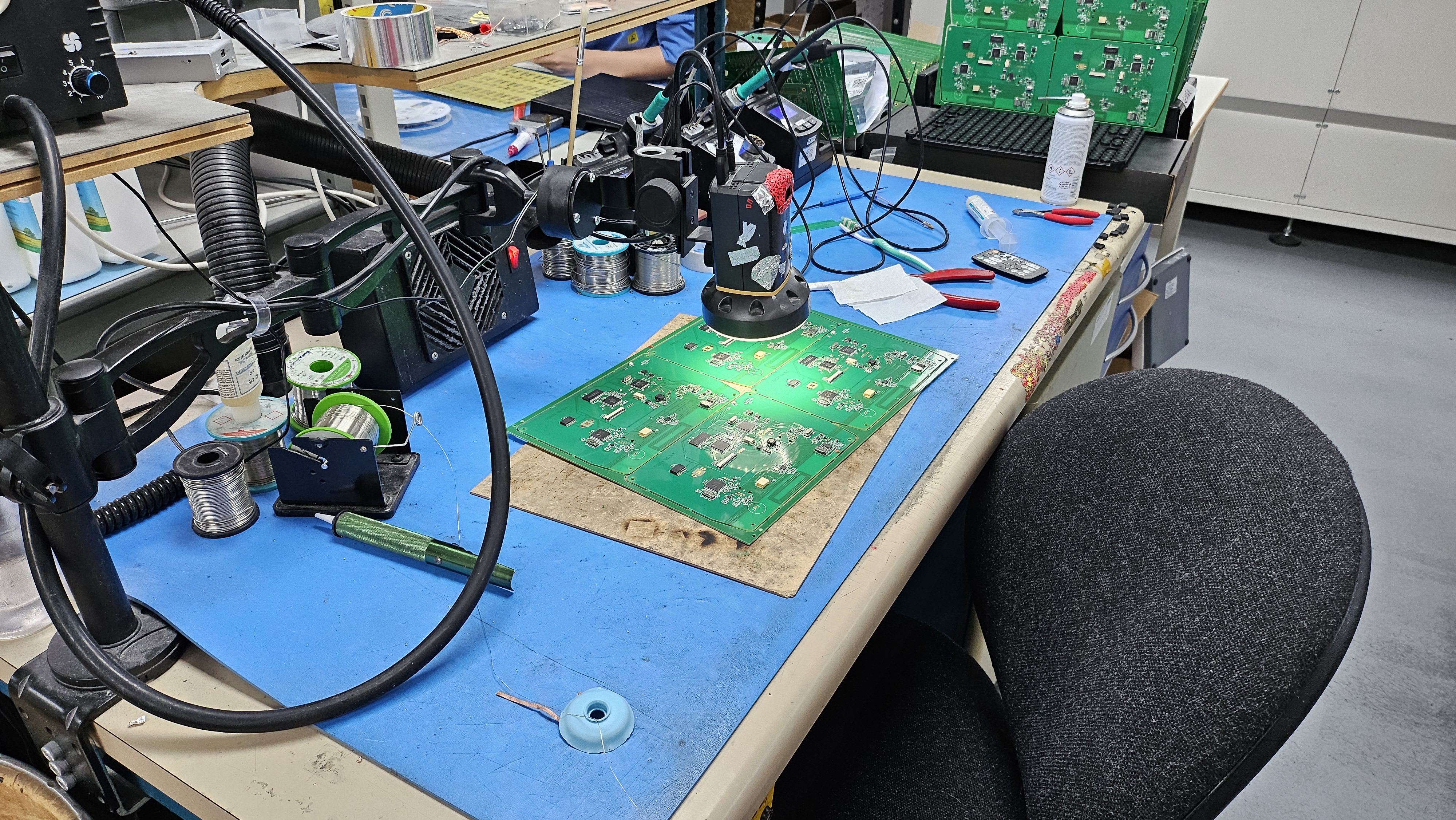

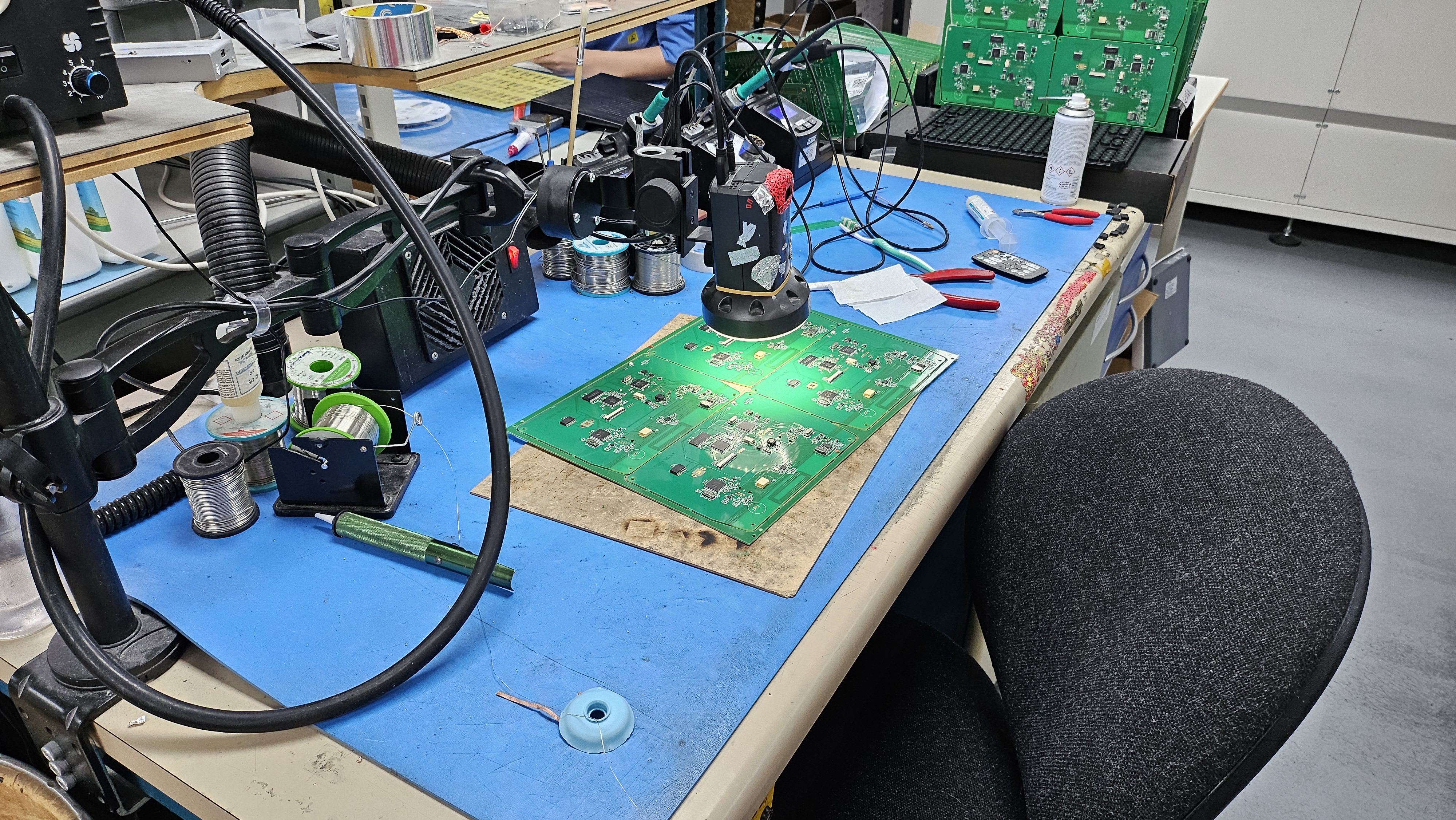

Our advanced facility in West Sussex, equipped with five surface mount lines and backed by a team of seasoned experts, ensures that each project achieves the highest standards of precision and efficiency.

From initial prototype to large-scale production, our surface mount assembly services are tailored to bring your electronic components to life with exceptional quality and speed.

GBE's production staff are Certified IPC Specialists to the standard J-STD-001, to ensure they are equipped with the latest industry knowledge and skills

Our surface mount assembly service, using the latest technology, includes the following:

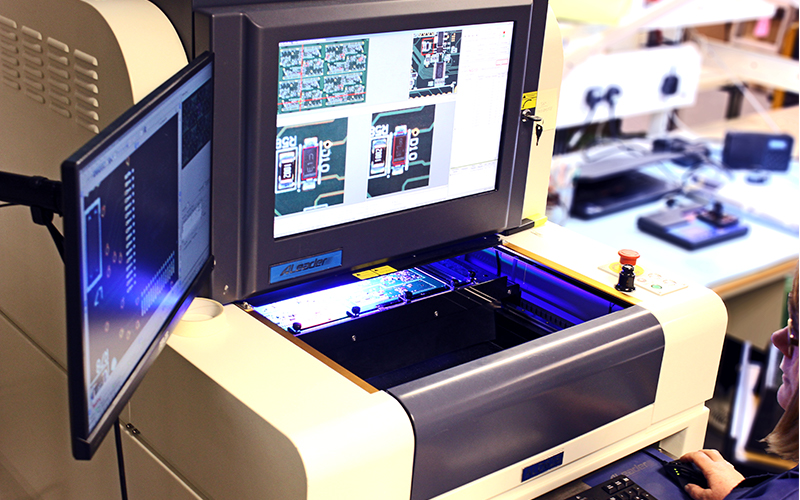

Our facility is equipped with the latest in surface mount technology, including:

Why Choose GB Electronics for Surface Mount Assembly?

Choosing GB Electronics as your partner in surface mount PCB assembly guarantees you a service founded on quality, precision, efficiency, and value add.

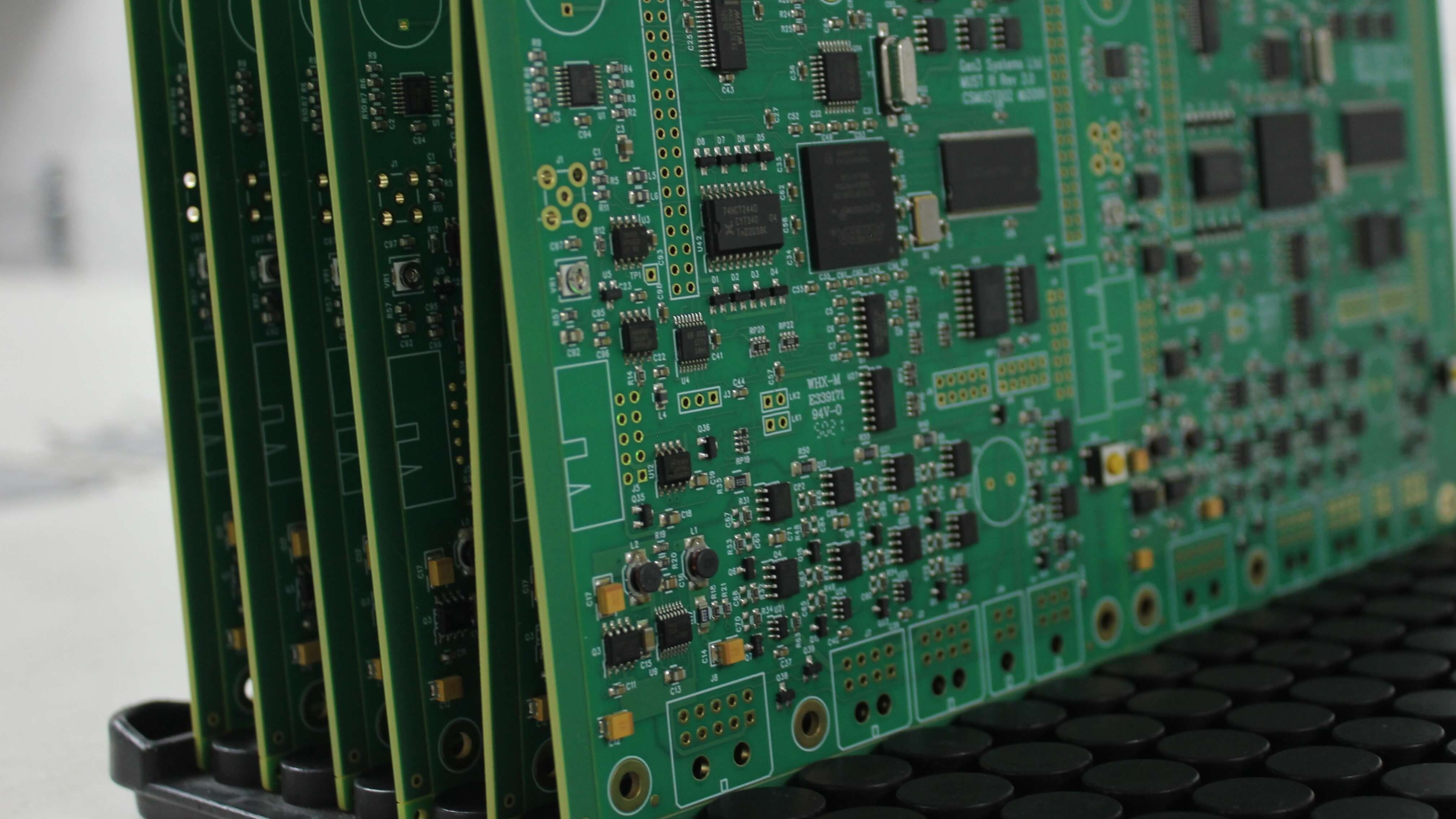

Our extensive capabilities in managing a wide range of surface-mounted components of all sizes and types, and printed circuit assemblies set us apart as the preferred provider for numerous industry sectors.

We are committed to ongoing innovation to deliver faster, more cost-effective, and superior surface mount assembly solutions.

Our dedication to excellent customer service ensures that we not only meet but exceed expectations. We provide comprehensive support and strategic advice to enhance your projects' manufacturability and efficiency. Trust GB Electronics to deliver a seamless, high-quality PCB assembly experience tailored precisely to your needs.

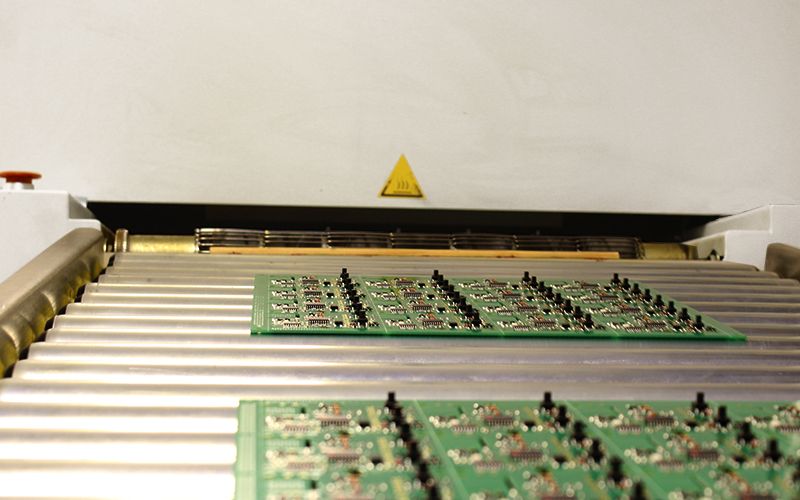

Our state-of-the-art automated assembly line, which includes industry-leading Europlacer iineo+ II pick-and-place machines, is at the core of our operations. These machines efficiently manage up to 60,000 components per hour, even accommodating the minutest components (e.g. 0201 sizes) with remarkable precision. This capability allows us to uphold a high throughput while ensuring the quality and accuracy required in modern PCB assembly.

Our production engineering team is the backbone of our surface-mount PCB assembly services. With extensive experience in manufacturing across various assemblies and industries, our team brings a wealth of knowledge and adaptability to each project. This expertise is crucial in offering a high-mix PCBA service that accommodates small, medium, and large batches (10-10,000 units) across multiple sectors with confidence and reliability.

At GB Electronics, quality is not just a goal but a fundamental aspect of our operation. Our stringent Quality Management System (QMS) underpins every process, ensuring that from the initial design to the final assembly, every step is monitored and controlled for quality. This system allows us to maintain the highest production standards, ensuring that each surface-mount PCB assembly meets our clients' specifications and industry benchmarks.

Understanding the diverse needs of our clients, we offer tailored solutions that range from prototype assemblies to full-scale production batches. Whether you need small and medium batch sizes, functional testing, or reflow and re-work services, our facility is equipped to handle the complexities and challenges of modern PCB assembly projects. We ensure all product runs have 100% Automatic Optical Inspection (AOI) applied.

Tell us about your project

Ready to embark on your next project? Contact GB Electronics today and let us discuss how we can assist you in creating efficient, compliant, and innovative electronic products. Reach us at +44 (0) 1903 244 500 or email us at info@gbelectronics.com

GB Electronics