At GB Electronics, we are committed to delivering exceptional product design consultancy services tailored to your specific needs.

Based near the south coast in West Sussex, we provide comprehensive support throughout the concept-to-manufacture process, helping turn your product ideas into production-ready solutions.

Whether you're innovating in electronics, software, or mechanical systems, our in-house teams offer end-to-end expertise—from early-stage concept development to compliance and manufacturing support.

As a long-term design partner, we work with clients in a range of industries, including medical devices, industrial automation, consumer electronics, and connected technologies.

At GB Electronics, our design offering is built around six fully integrated disciplines, enabling us to deliver cohesive, production-ready solutions tailored to your product's unique requirements. Each area of expertise is delivered in-house, ensuring seamless collaboration, efficient project management, and complete control from specification through to compliance and validation.

Explore examples of our work to see how our cross-functional teams combine electronics, software, mechanical design, and regulatory expertise to deliver exceptional results. Every project is governed by our ISO 9001:2015-certified quality management system — a reflection of our commitment to robust, repeatable design processes.

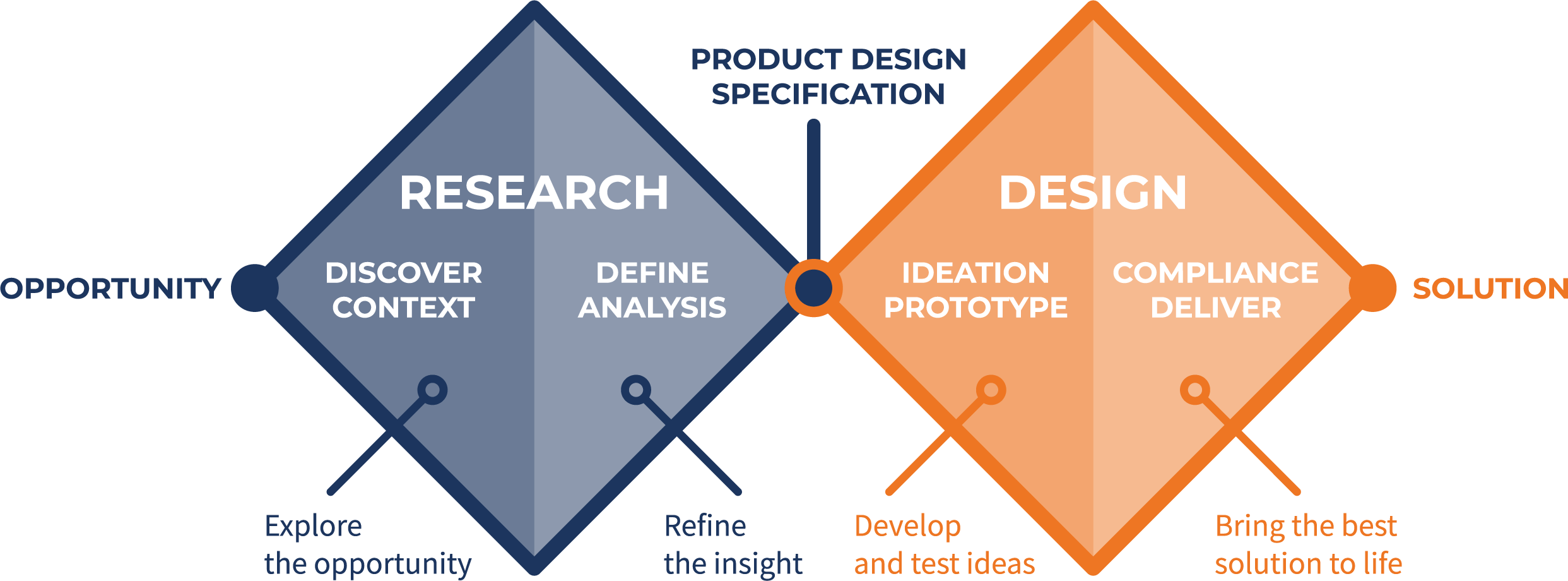

As a leading UK product design consultancy, our process is structured yet adaptable — designed to suit each project's technical and commercial demands. Whether you're seeking full lifecycle development or input at a specific stage, we provide the clarity and control needed to move confidently from idea to implementation.

We follow four key phases as part of our concept to manufacture model:

Want to find out more about our design process? Check out our article: "The Product Design Process: ..."

GB Electronics is more than a design provider — we're a long-term development partner. With over four decades of experience in product innovation, we offer the technical depth, process rigour, and cross-disciplinary expertise needed to bring complex ideas to life.

Here's what sets us apart:

If you're looking for a product design consultancy that can guide you through the concept to manufacture process with precision and reliability, we're here to help.

Speak to our West Sussex team to discuss your requirements — whether you're at the initial concept stage or looking to optimise an existing design.