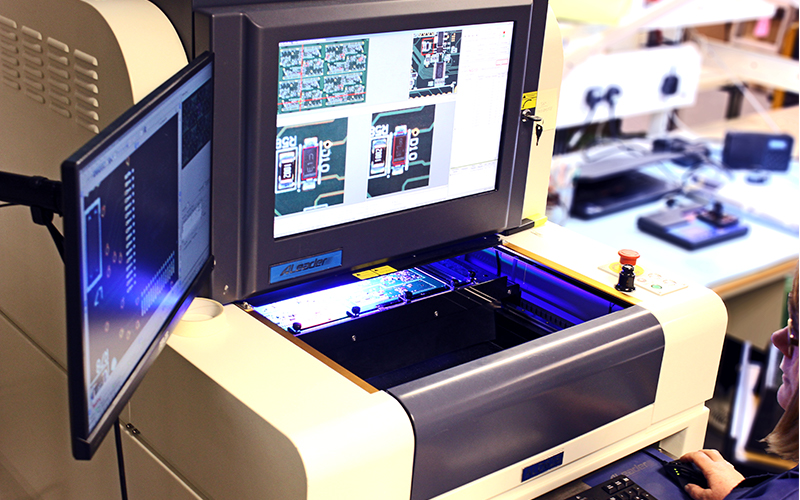

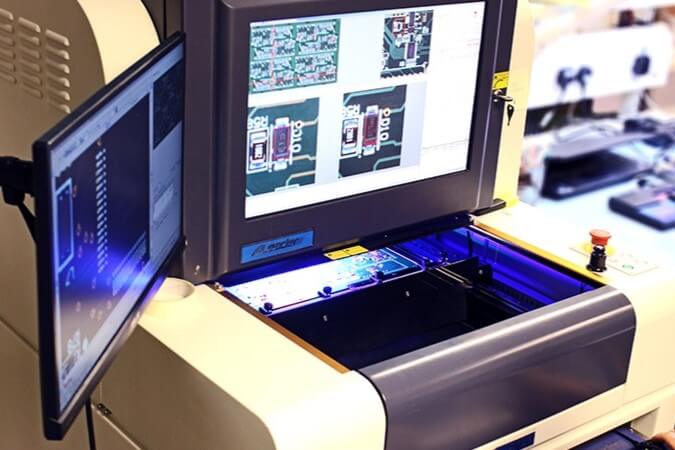

Ensure the highest quality for your PCB assemblies with GBE's state-of-the-art Automatic Optical Inspection (AOI) services.

By leveraging advanced AOI technology, we guarantee fast, accurate, and reliable inspection for every electronic component, preventing costly errors and ensuring flawless production

We test every single individual board assembly with our automatic optical inspection process.

Trust GBE for your PCB assembly needs and experience unparalleled precision and quality.

Contact us today to learn how our AOI services can enhance your production line and deliver superior results.

Advantages of AOI:

Our machines include:

Why Choose GBE for AOI Services?

GBE offers unparalleled expertise in PCB assembly and inspection.

Our advanced AOI machines from ALeader and Mirtech, combined with digital inspection cameras, ensure precise defect detection and high-quality PCB integrity.

We provide customised AOI services to meet your specific needs, detecting faults early to prevent costly rework and delays.

Our learning AOI software continually improves inspection accuracy, covering defects such as open circuits, shorts, solder thinning, tombstoning, and component errors.

We pride ourselves on exceptional customer support, guiding you through every step of the inspection process. Our commitment to excellence ensures that we invest in the best technologies and skilled professionals. Choose GBE for reliable, top-quality AOI services. Contact us today to enhance your PCB assembly projects.

What is Automatic Optical Inspection?

Automatic Optical Inspection (AOI) is a technology used in PCB manufacturing to scan boards for defects using cameras and advanced software. It detects issues like open circuits, shorts, thinning solder, incorrect, missing, or misaligned components. AOI ensures high-quality standards by identifying faults early in the production process, preventing costly rework and delays.

Essential for modern, complex PCBs, AOI machines continually improve their accuracy through adaptive learning software, making them indispensable for precise and reliable inspections.

At GBE, we utilise advanced Automatic Optical Inspection (AOI) equipment to ensure the highest quality in PCB assembly.

Our cutting-edge machines and tools include:

Our state-of-the-art AOI equipment ensures that every PCB leaving our production line meets the highest standards of quality and reliability.

Choosing GBE for your Automatic Optical Inspection (AOI) needs offers numerous advantages:

Trust GBE for reliable, precise, and efficient AOI services.

Tell us about your project

Ready to embark on your next project? Contact GB Electronics today and let us discuss how we can assist you in creating efficient, compliant, and innovative electronic products. Reach us at +44 (0) 1903 244 500 or email us at info@gbelectronics.com