Insights

GB Electronics

As demand for high-quality, locally manufactured electronics continues to grow, the need for agile, high-performance surface mount assembly (SMA) solutions has never been greater. At GB Electronics, we’ve responded with significant investment in next-generation SMT machinery, boosting our production capability and reaffirming our commitment to delivering precision and efficiency at scale.

Our two newly acquired SMT machines represent a step change in both speed and accuracy. Built for modern, high-throughput environments, they can place hundreds of thousands of components per hour, allowing us to support everything from rapid turnaround prototyping to full-scale production runs.

This translates into faster time to market, tighter tolerances, and consistently high build quality for clients. These machines also offer enhanced flexibility for complex board layouts and fine-pitch components, broadening the scope of projects we can support.

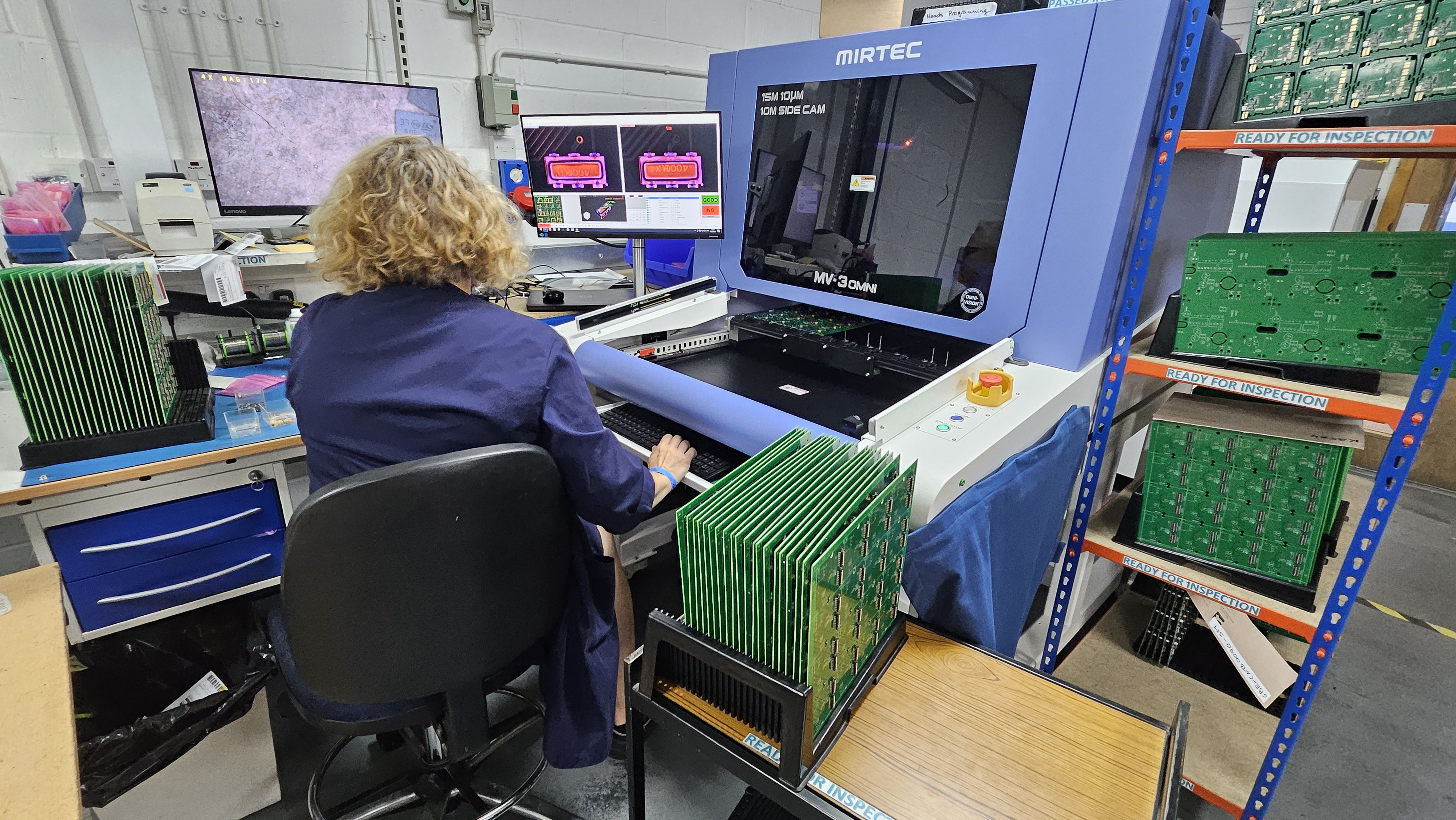

Where many in the industry rely on batch sampling for quality assurance, GB Electronics goes further. Every single PCB produced undergoes full optical inspection — not just a representative few. Our advanced 3D AOI (Automated Optical Inspection) systems meticulously check each board for placement accuracy, solder joint quality, and component alignment.

This comprehensive approach significantly reduces the risk of errors reaching the next stage of your process, offering peace of mind that your product will perform reliably every time.

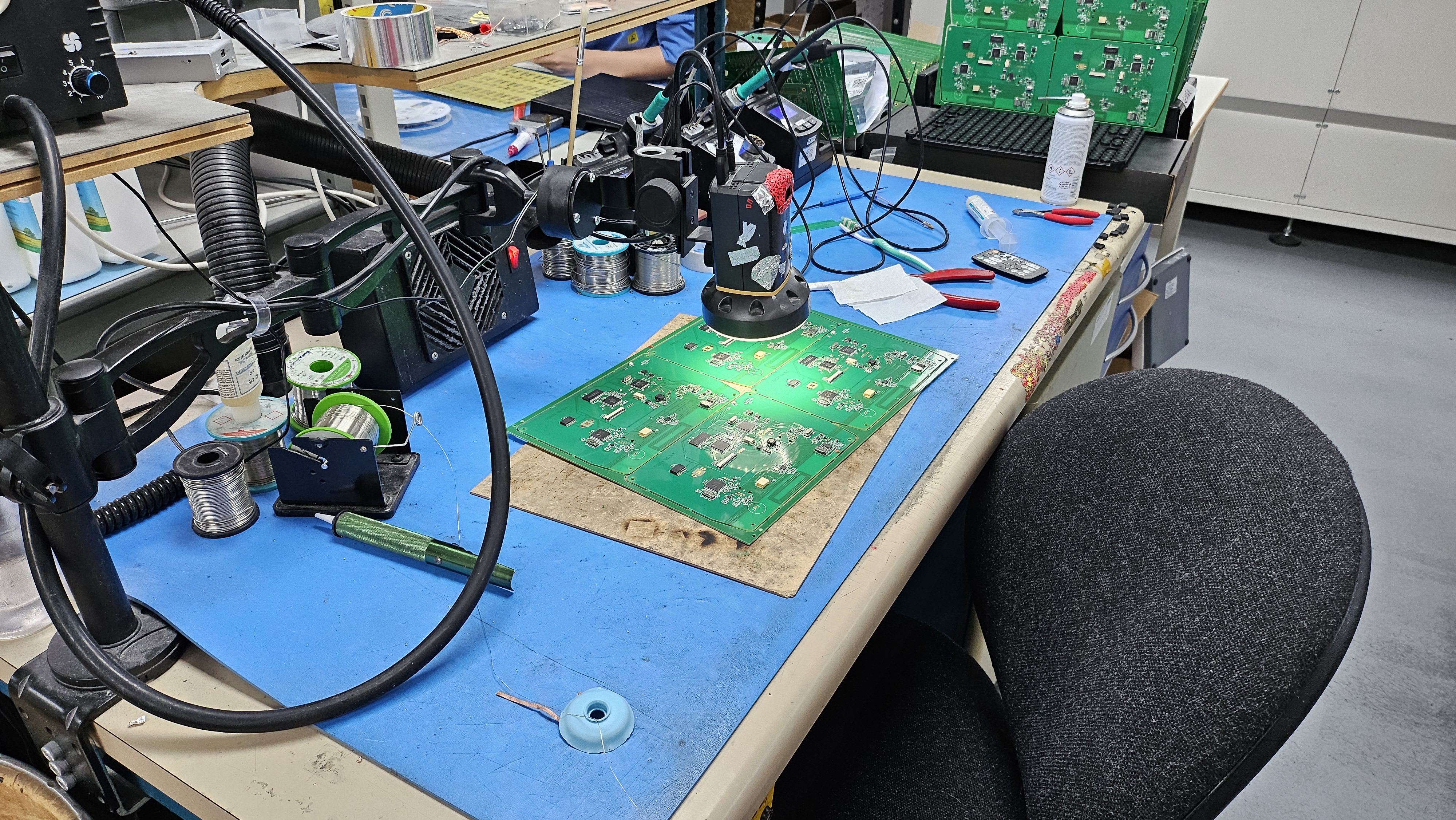

Technology alone doesn’t deliver results — people do. Our experienced team of technicians, engineers, and production specialists play a critical role in maximising the potential of our equipment. Every project benefits from a collaborative, detail-focused approach to process optimisation and quality control.

We’re not simply a factory line; we’re a partner. That means adapting to your project requirements, advising on manufacturability, and ensuring that even the most technically demanding builds are completed with precision and care.

Located in West Sussex, GB Electronics provides local support to businesses looking for responsive service without compromising on capability. Whether you're a start-up scaling your first production run, or an established manufacturer seeking a more reliable partner, our SMA facility is built to adapt to your needs.

In addition to surface mount assembly, we offer a complete suite of supporting services, including component sourcing, kitting, BOM analysis, and design-for-manufacture (DfM) expertise — making us a true end-to-end partner in your electronics journey.

With additional capacity now available, we're actively welcoming new clients who require high-quality, high-volume surface mount assembly services. If you're ready to work with a manufacturing partner offering precision, speed, and scalability — backed by a dedicated team and the latest SMT technology — we'd be delighted to discuss your requirements.

Ready to start a conversation? Get in touch with our team to discuss your next project.