Insights

GB Electronics

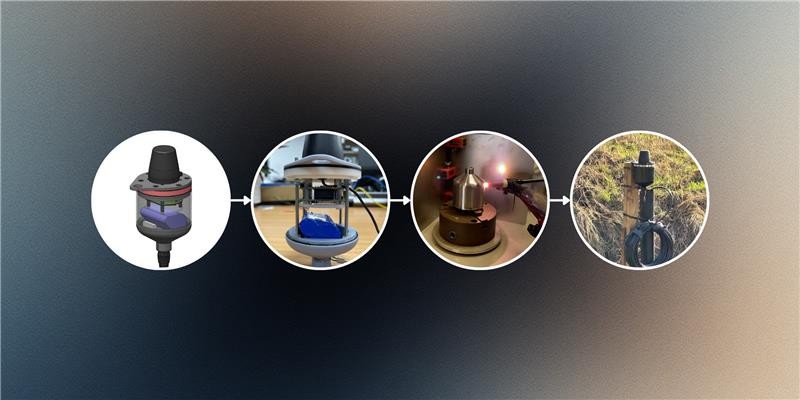

Why Design for Manufacture Shouldn’t Wait Until the End

In product development, timing is everything. A strong concept and a functional prototype are essential, but they don’t guarantee success. One of the most common reasons a project might stall before production is that Design for Manufacture (DfM) was considered too late in the process.

At GB Electronics, we work with clients across a wide range of sectors – from medical to industrial electronics – and we see this pattern all too often. This article explores why DfM should be embedded from the start, and how it can help reduce risk, lower cost, and accelerate time to market.

The Cost of Late-Stage Surprises

It’s not uncommon for a product to function perfectly during prototyping, only to encounter issues once production begins. These issues are often preventable and stem from early design decisions made without manufacturing input. Common examples include:

• Component availability issues – parts chosen early on that later become obsolete or difficult to source.

• PCB layout inefficiencies – designs that complicate automated assembly or increase inspection and test time.

• Manufacturing constraints overlooked – features that can’t be easily machined, moulded, or assembled without costly redesigns.

• Tolerance mismatches – dimensional inaccuracies that make assemblies difficult to fit or inconsistent in quality.

Each of these can result in redesigns, schedule delays, and increased cost just when a project should be moving smoothly into production.

What Design for Manufacture Actually Means

DfM is a practical approach that ensures a design can be efficiently, repeatably, and reliably built at scale. It relies on early collaboration between engineers and manufacturing specialists so design intent aligns with real-world production capability.

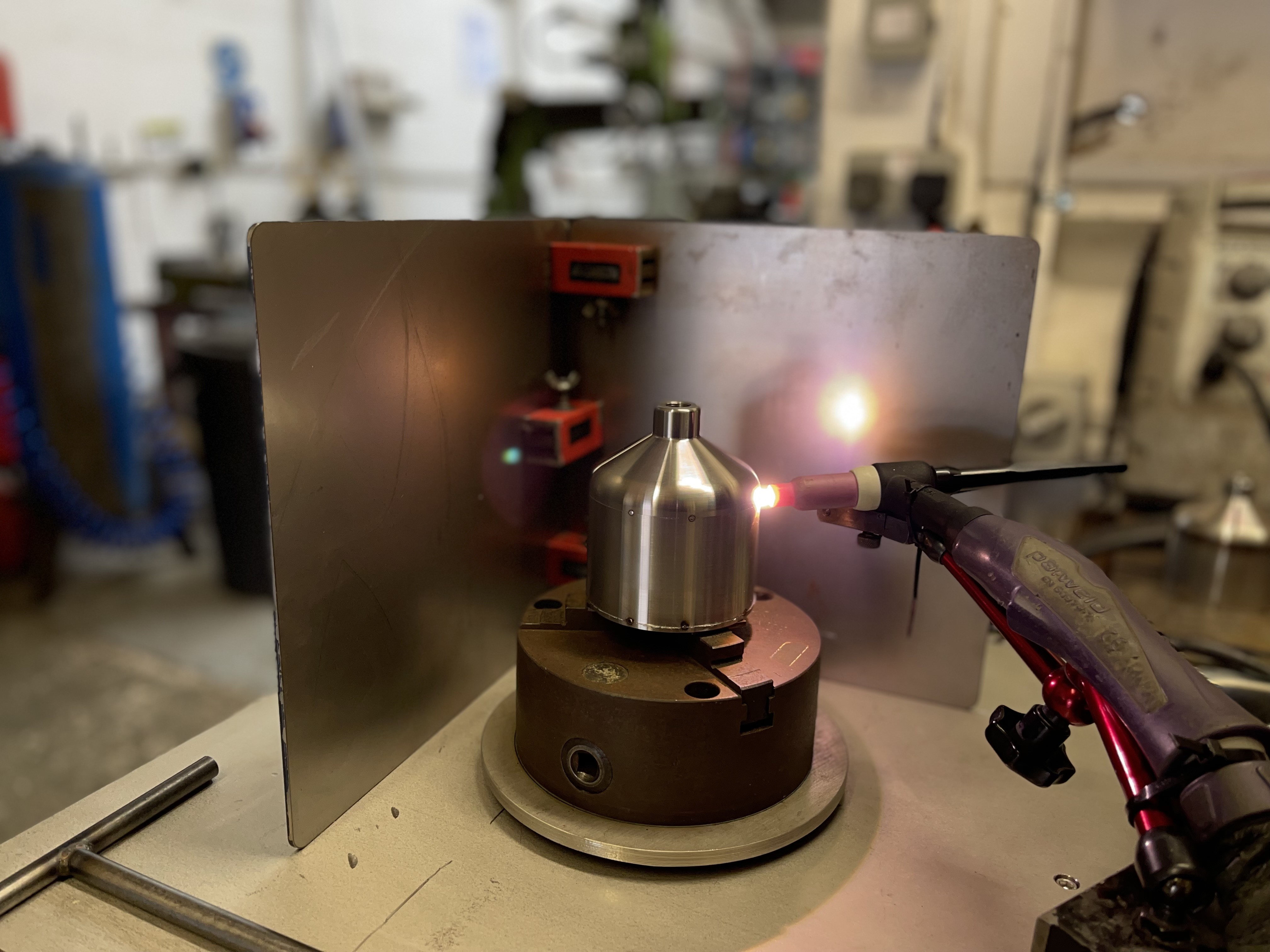

A core principle of DfM is that the manufacturing process defines the design’s boundaries. For example, injection moulding requires draft angles, suitable wall thicknesses, and clean parting lines. Ignoring these can lead to tooling complications and surface defects. Similarly, material selection directly influences which processes are viable: a complex metal enclosure might be CNC machined for low volumes or die cast when producing at scale.

Different manufacturing methods also offer varying tolerance levels, so understanding these early helps ensure that assemblies fit correctly without post-processing or costly adjustment.

At GBE, DfM informs every stage of product development, including:

• Component selection – choosing parts with stable supply chains and suitable packaging for automated assembly.

• PCB layout – optimising for pick-and-place efficiency, solderability, and test coverage.

• Mechanical design – aligning geometry, materials, and tolerances with the intended manufacturing process.

• Test point accessibility – incorporating features that support reliable, repeatable production testing.

Benefits of a DfM-First Approach

Embedding DfM early in development reduces risk and improves overall project efficiency. Key • Shorter development cycles – fewer iterations between design and production.

• Lower cost – by avoiding tooling changes, material waste, and redesigns.

• Greater reliability – designs optimised for repeatability and consistent quality.

• Faster time to market – through smoother production ramp-up.

How GBE Integrates DfM Into Every Project

Because GBE offers both design and full-scale manufacturing in-house, our teams collaborate from day one. Design decisions are informed by direct manufacturing experience, not assumptions.

Formal DfM reviews are built into our workflow, covering everything from PCB manufacturability and solder mask design to tolerance analysis and fixture compatibility. Early assembly trials further ensure a seamless transition to production.

This integrated approach allows our clients to launch products with greater confidence, fewer revisions, and a more predictable path to market.

Conclusion

Whether you're developing a single-board industrial controller or a multi-board consumer product, DfM should never be an afterthought.

A small investment in production-aware design early in development can save months of rework – and significantly reduce the risk of failure at the final hurdle.

To learn more about how GBE can support your next project with a DfM-first approach, email us at info@gbelectronics.com.