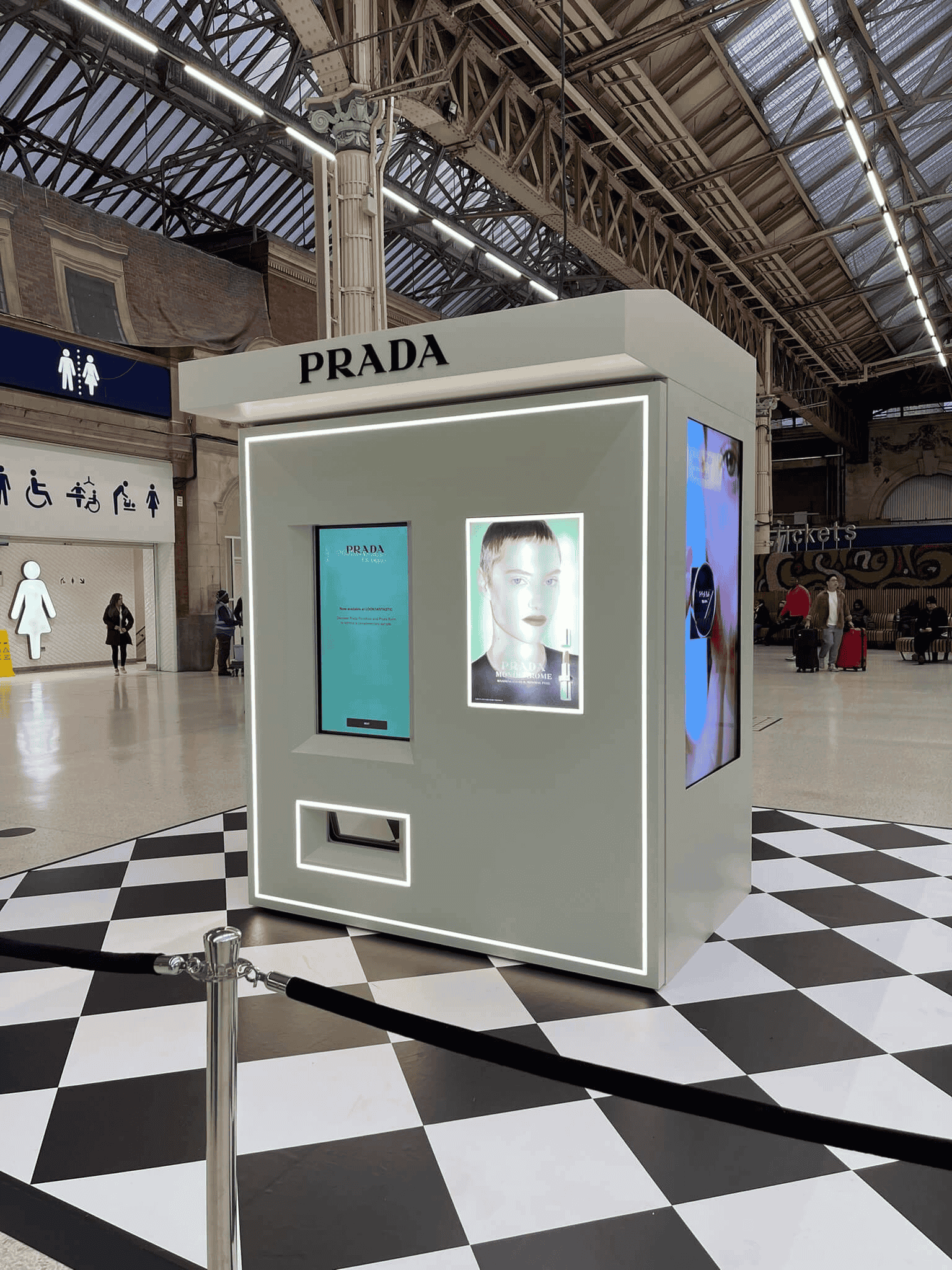

This vending machine gives consumers complimentary samples of their preferred perfume in return for their accurate and honest feedback.

Odore is an innovative marketing platform for sampling campaigns. Odore work alongside their clients to build unique customer experiences and journeys for their target audience. This is done across multiple channels in the online space as well as through instore interactive services. Through this, Odore’s clients gain data to further personalise the end user experiences and hyper-target customers through their platform.

As specialists in digital marketing campaigns, Odore had a desire to expand into physical marketing and this prompted them to approach GBE to help achieve this. Their idea was to put top class perfume brands into convenient public locations via smart vending machines.

Odore first approached GBE in December 2019, they were unfortunately let down by another company who had previously produced prototype versions of the smart vending machine but were unable to meet production demands and some of the final technical challenges. GBE were able to pick up this project and resolve all the electronic issues with the prototypes. GBE produced and distributed the units while making sure they were compliant; this was all completed within the tight deadline.

With the success of this short-term project, Odore then contracted GBE to re-designing and produce a new smart vending machine. This led to the following core specifications:

One of the key design challenges of the project was the large size of the vending machine. From the specification, the touchscreen was increased from a 32” to a 43” display and the machine must be free standing. On top of the internal electronic dispensing mechanisms, this was a lot of weight to support. With so much weight, safety was a key factor in the development and ensuring it would pass tilt testing as per ISO-62368-1 as well as still being user friendly, functional, and retaining a good aesthetic design. This was achieved by counterbalancing the weight of the touch screen with the weight of the base. As the weight of the base increases, it becomes increasingly difficult for the vending machine to topple over due to the moment of a force. An internal frame was designed and constructed to provide structural rigidity and strength to the whole unit to support the weight of all the vending machines internal components and mechanisms, instead of using sheet metal which may buckle.

Another challenge was ensuring the dispensed products dropped safely without any electronics to save on cost. A full scale MDF prototype was built to test different ideas. Some of these ideas involved using silicone shock foam to absorb the impact as the products dropped, others included using various lifts and counter levers. The most effective and simplest solution came in using a tilted slide with a curved radius at the bottom, much like you see in some water parks! For this to be effective, the dispensed samples needed to be pushed against the back of the slide wall to prevent the dispensed product from dropping straight to the bottom of the machine. This was achieved by creating flexible guides that would allow smaller samples to slide down through the provided gaps, while giving way to and countering the accelerating descent of the larger and/or heavier samples. This proved to be the most functionally and mechanically efficient way of safely dispensing samples whilst keeping production costs low.

The project was completed within a very tight time schedule, with the first device being shipped to Japan. This was achieved through our dedicated Full Product Assembly team as well as utilizing our strong partnerships with Local Manufacturing Specialists to deliver the product within the time schedule.

The smart vending machine works by giving consumers complimentary samples of their preferred products in exchange for completing a short survey. The data collected provides the client with unique consumer insights to boost sales, increase engagement and help product development. Key features include: