Developing a successful electronic product requires more than just technical know-how—it demands a clear understanding of market needs, user expectations, and a highly structured approach to design and engineering. At GB Electronics (GBE), we use the Double Diamond design framework to guide our clients through every stage of the process—from identifying opportunities to delivering a market-ready solution.

With in-house capabilities covering electronics, firmware, software, mechanical design, and production, we take ideas from initial concept to certification and manufacture, ensuring that functionality, usability, and commercial value are prioritised.

1. Discovering the Opportunity

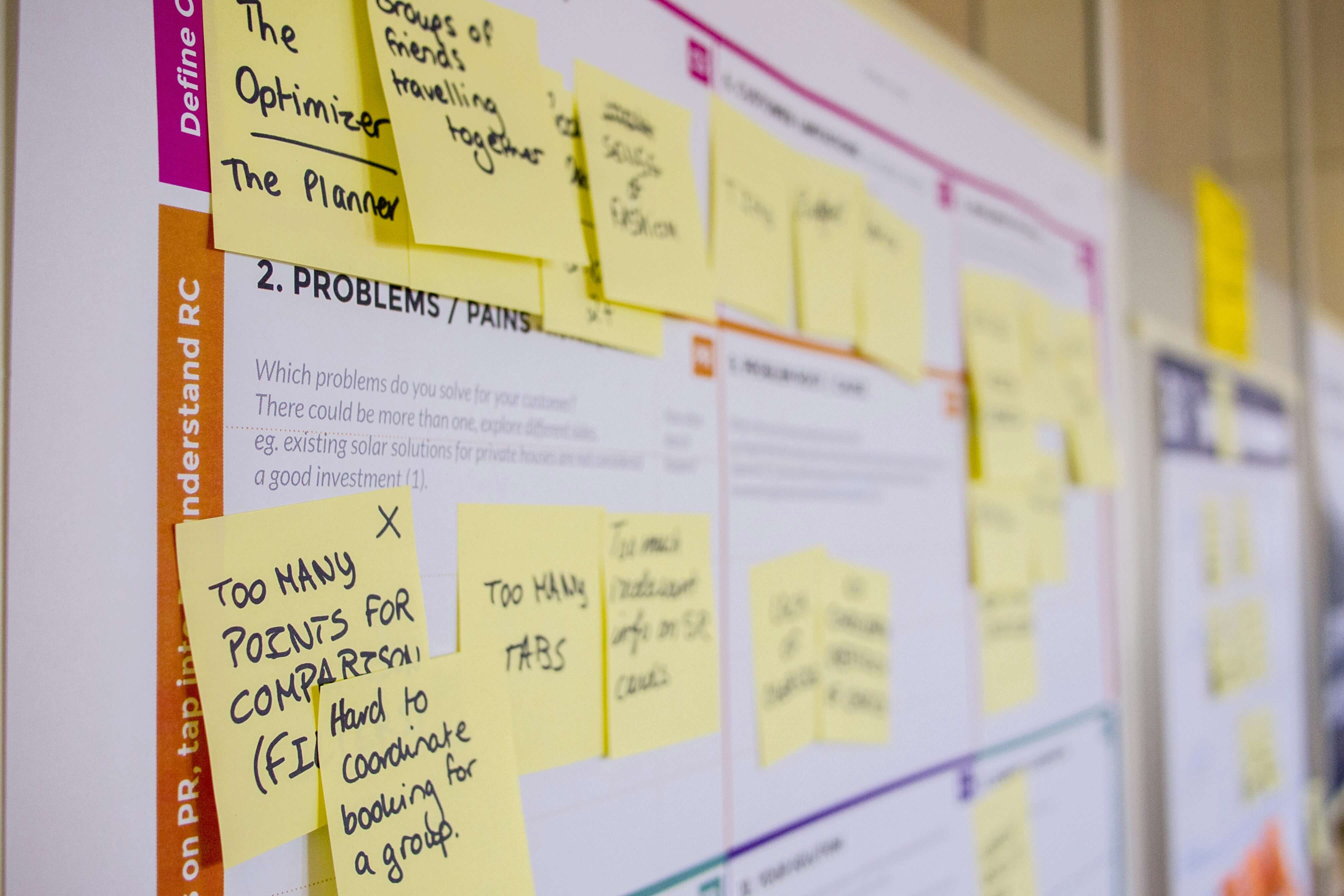

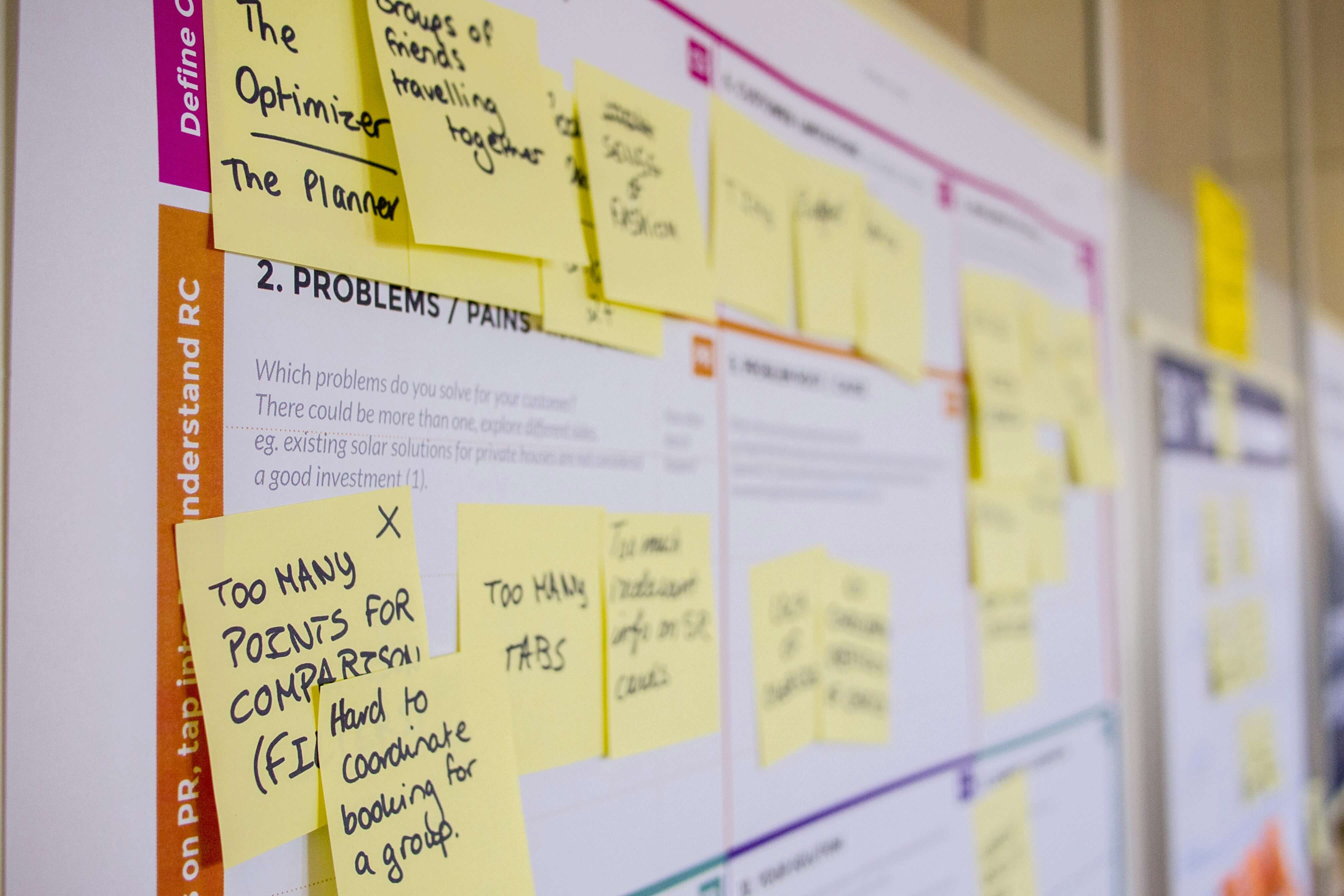

Every product begins with a clear understanding of the problem it’s designed to solve. This discovery phase sets the foundation for the rest of the design process.

Key activities include:

- Identifying Core Problem and Opportunity – What gap or challenge does the product address?

- Market Research & Opportunity Analysis – Reviewing market trends, competitive products, and emerging technologies.

- Target Audience Identification – Understanding the intended user's needs, behaviours, and environments.

- Pinpoint Analysis – Pinpointing the end users frustrations or inefficiencies the product can resolve.

- Feasibility Study – Evaluating the technical, regulatory, and commercial viability of the concept.

2. Defining the Concept

With a validated opportunity in hand, we begin shaping the product concept. This involves aligning technical requirements with user needs and business objectives.

Key stages in this phase:

- Defining Product Concept – Outlining core functions and initial design intent.

- Feature Definition – Determining which features are essential for the product’s success.

- Value Proposition – Identifying what makes the product compelling in the eyes of the customer.

- Product Design Specification – Create a high-level design brief that documents key performance parameters, constraints, and regulatory requirements to guide the design process.

3. Ideation and Design Exploration

This stage encourages creative problem-solving, turning ideas into workable technical solutions while ensuring a strong user experience.

Activities include:

- Ideation – Generating a range of potential solutions through sketches, diagrams, and collaborative workshops.

- Technical Solutions – Investigating circuitry, firmware, embedded systems, connectivity, and user interface options.

- Early-Stage Compliance Considerations – Identify standards (CE, UKCA, EMC, etc.) relevant to the product from the outset.

- Ergonomics and Usability – Designing for intuitive use and comfort across physical and digital interfaces.

- Form and Aesthetics – Exploring visual design, brand alignment, and industrial design to ensure market appeal.

4. Developing a Minimum Viable Product (MVP)

The MVP stage focuses on building a product version with just enough features to validate technical performance and user interaction.

This includes:

- Minimum Viable Product (MVP) – A core-function prototype to prove key assumptions.

- Refine Design Details – Iterative design improvements based on internal testing and stakeholder feedback.

- Visualise the product in a Real-World Context (CAD) – Using 3D CAD tools to assess spatial design, integration of components, and product assembly.

5. Engineering and Prototyping

With the design direction established, the focus shifts to engineering feasibility and hands-on prototyping.

Capabilities include:

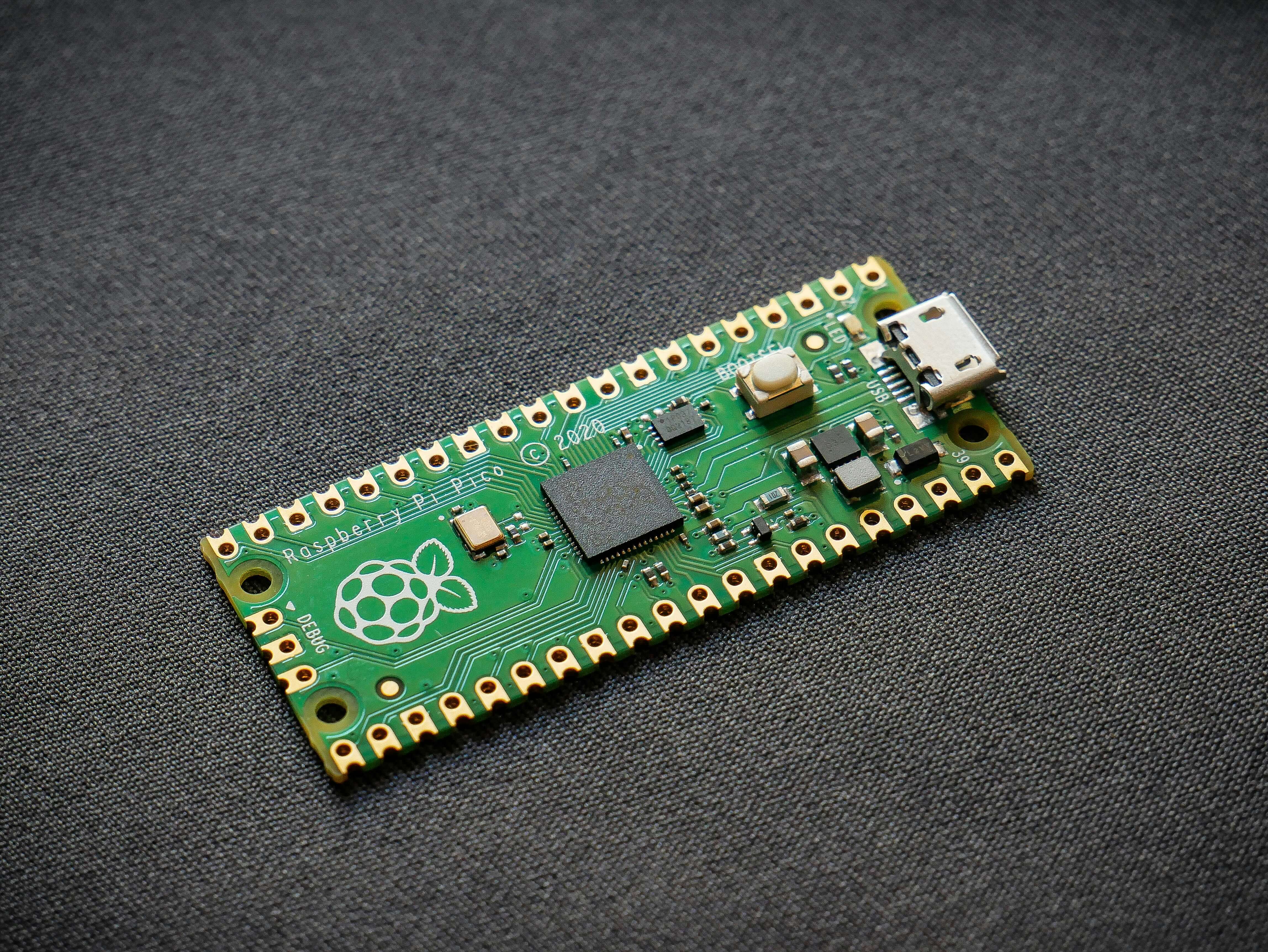

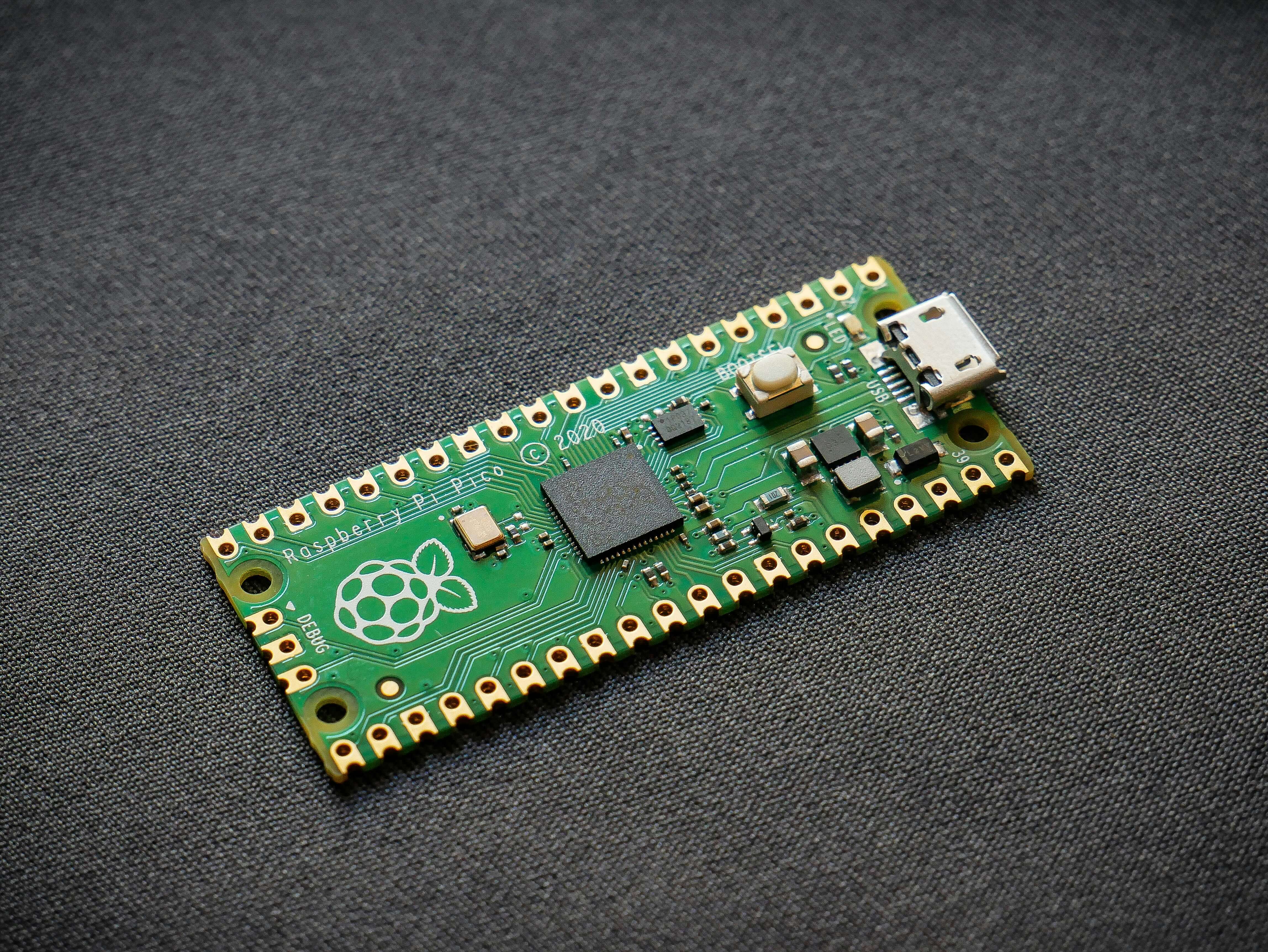

- Detailed Electronics Design, Firmware and Software Development – Creating circuit schematics, PCB layouts, embedded code, and application logic.

- Rapid Prototyping and Iterative Testing – Validating both form and function through repeated physical testing:

- 3D Printing – Quick-turn mechanical models for fit and appearance.

- CNC Machining – High-precision prototypes using production-intent materials.

- Electronics Prototyping – Development kits and custom PCBs for evaluating circuit behaviour.

- Prepare Early Stage Testing – Assembling pre-production units for functional testing and user feedback.

- Validation and Verification – Confirming that the product meets defined specifications, safety requirements, and user expectations.

6. Preparing for Manufacture

With a refined and validated prototype, attention turns to preparing the design for production and market launch.

This includes:

- Preparing for Manufacture – Finalising all documentation, bills of materials, and manufacturing plans.

- Design for Manufacturability (DFM) – Optimising design for cost-effective, reliable production at scale. This is also considered at an early stage of the project as well.

- Final Testing & Certification – Coordinating third-party compliance testing (e.g., CE, UKCA, FCC) and internal quality control procedures.

- Material and Supplier Selection – Choosing appropriate suppliers for enclosures, components, and packaging based on cost, lead time, and quality.

- Product Launch – Supporting packaging design, user documentation, and distribution planning for successful go-to-market execution.

- Small-Batch and Mass Production – Manufacturing initial production runs through to full-scale rollout.

- Quality Assurance – Implementing rigorous test procedures to ensure consistent build quality, performance, and reliability.

Final Thoughts

At GB Electronics, our approach to product design is rooted in process, precision, and technical excellence. By following a clearly defined framework—from opportunity identification through to manufacturing—we ensure each product we develop is fit for purpose, commercially viable, and technically robust.

Whether you're in the early stages of an idea or preparing for product launch, our cross-functional team is ready to support your journey.

Speak to our product design team to find out how we can help bring your concept to life.